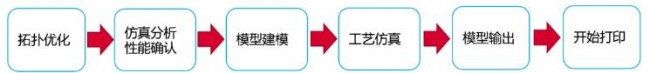

One interesting example of how this workflow is applied can be seen on the manufacturing of a 3D printed robot arm.ĭutch company MX3D recently collaborated with Altair to 3D print an optimized industrial robot arm. He therefore benefits from an automatic creation of geometry while ensuring the part meets the performance requirements and that this part is manufactured without any defects. Inspire Print3D simplifies the identification and correction of potential deformation, delamination and excessive heating issues before building a part.įurther manufacturing process analyses can be performed leveraging third-party tools available through the Altair Partner Alliance, all on one license.As far as the other steps to achieve a successful design for manufacturing are concerned, Kunju also lays emphasis on the fact that the engineer should take into account the manufacturing design rules when it comes to generative design. Reducing expensive trial and error by simulating part build, cooling, cutting and springback, Inspire Print3D delivers designs having the fewest supports, optimally oriented on the print bed. By capturing behavior independent of the printer type, with Inspire Print3D designers can evaluate and easily modify critical process variables.

The advanced thermo-mechanical simulation enables design engineers to develop parts ready for additive manufacturing. Design alternatives can be quickly explored and evaluated without leaving the familiar Inspire user environment. Starting from either topology optimization results or an imported CAD geometry, support structures can be easily generated and optimized. As a result, teams to cut product development and additive manufacturing costs by reducing material usage, print times and post-processing. Inspire Print3D accelerates the creation, optimization, and study of innovative, structurally efficient 3D-printed parts, providing a fast and accurate toolset for the design and process simulation of selective laser melting (SLM) parts.Įngineers can quickly understand changes to process or design that affect manufacturability, then export part and support structure geometry to major printer preparation software to produce the part.

Altair® Inspire™ Print3D Efficient Design for Additive Manufacturing

0 kommentar(er)

0 kommentar(er)